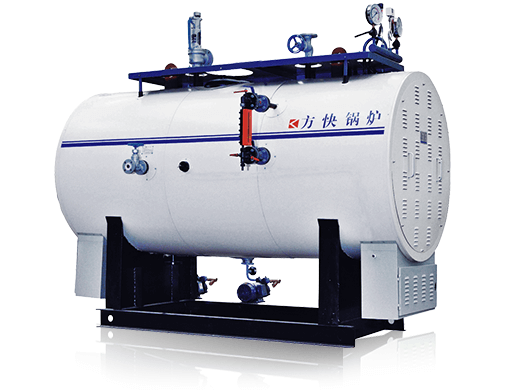

There is a strong demand for steam in the processing of paper mills, and the production processes such as pre-adjusting corrugated base paper, forming, gluing and bonding are inseparable from steam. It can be said that steam boilers are one of the key equipment of corrugated paper production enterprises. With the development of the industry, the paper mill is facing increasingly fierce market competition and stricter national environmental protection policies, and the boiler equipment used by the enterprise is also facing an update. After the technical engineer of Zhengzhou Fangkuai Boiler customized the boiler design plan for it, the company purchased a gas-fired steam boiler with an output of 4 tons, which can fully meet the needs of the production line.