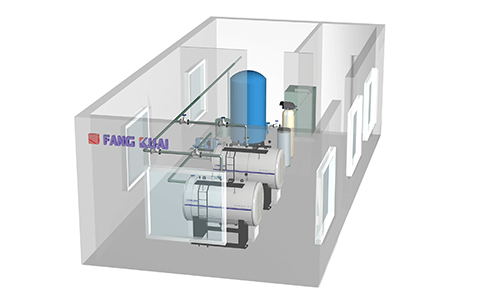

Electric Hot Water Boiler

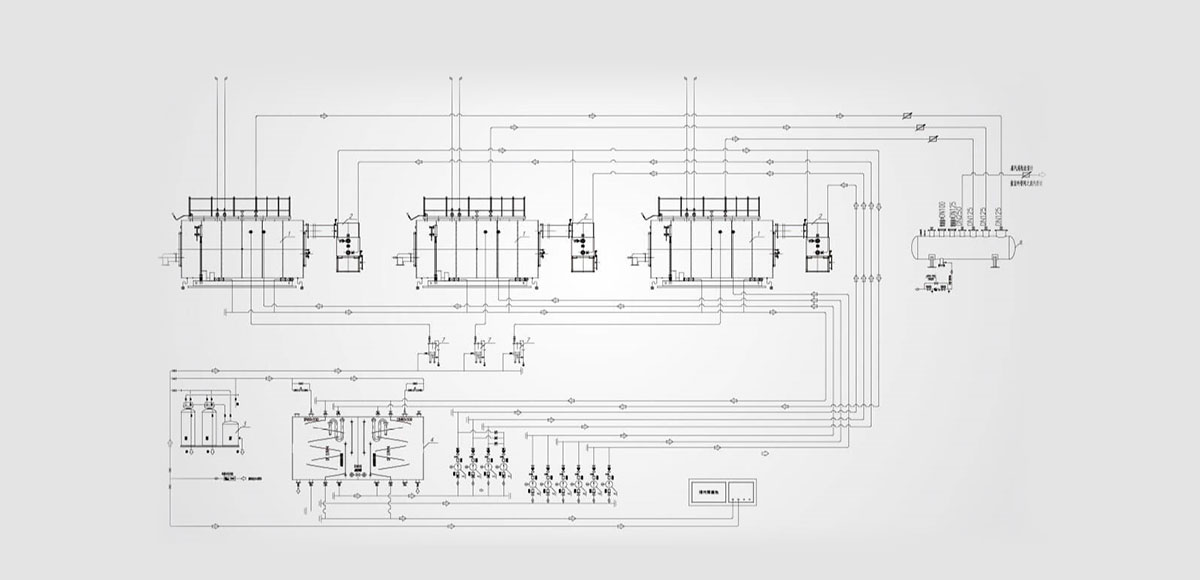

The boiler is composed of a boiler body, an electric control box and a control system, and has obvious characteristics of environmental protection, cleanliness, pollution-free, noise-free and automatic. With the reduction of limited energy and the sharp rise in price, electric hot water boiler as a new type of kinetic energy equipment is more and more recognized by people.

Rated thermal power: 0.1-2.8Mw

Rated thermal efficiency: 98%

Pressure: ≤1.0MPa

Available fuel: electric energy