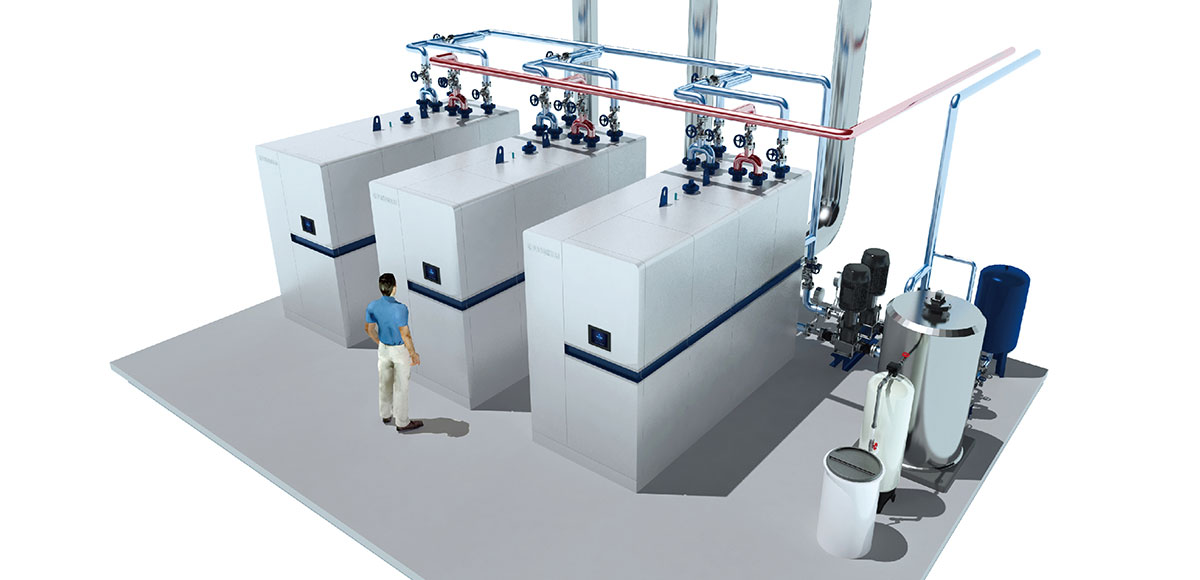

T6 Vacuum Hot Water Boiler

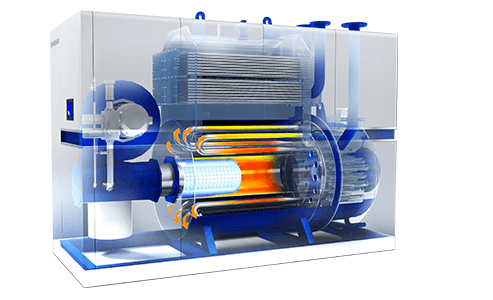

The boiler adopts an environmentally friendly combustion method - full premixed combustion, and the gas and air are precisely adjusted and premixed in advance to ensure more complete combustion. The new crossing wing-shaped heat exchange element, Ultra-speed Smoke Cooking Tube, uses a unique heat transfer technology and structural design to achieve deep condensation of flue gas and greatly improve heat transfer efficiency.

Rated thermal power: 0.7-2.8Mw

Rated thermal efficiency: 105.5%

Pressure: -0.02MPa

Available fuel: natural gas