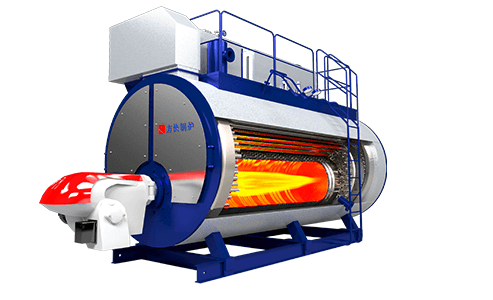

Gas(oil) Fired Integrated Hot Water Boiler

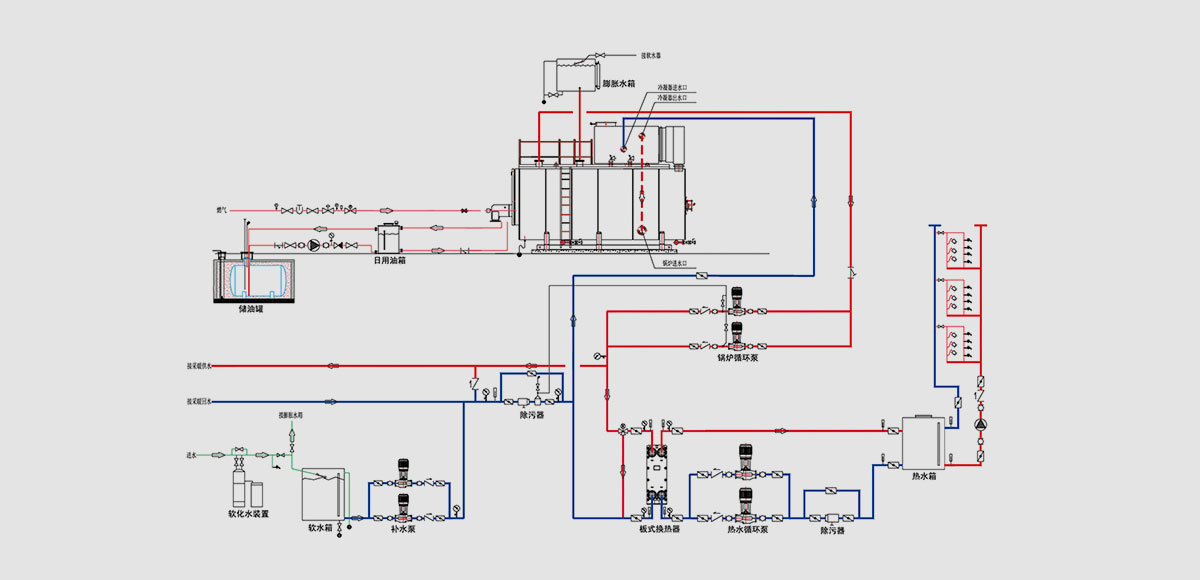

This series of boilers mainly use condensing technology to recover the residual heat of flue gas, making full use of the sensible heat and latent heat of flue gas. The boiler absorbs a large amount of heat again, so the exhaust gas temperature is only 50 °C, and the thermal efficiency can be increased by more than 10%, which can save at least 4% of fuel input.

Rated thermal power: 0.7-14Mw

Rated thermal efficiency: 96-98%

Pressure: ≤1.25MPa

Available fuel: natural gas, light oil, etc.