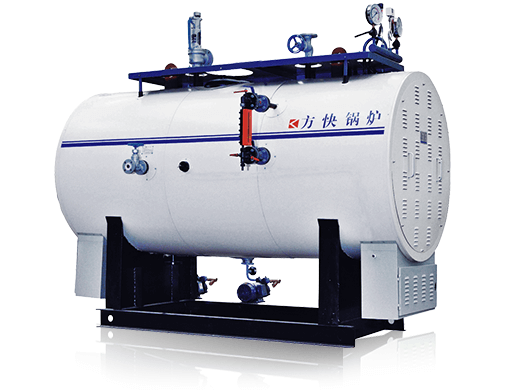

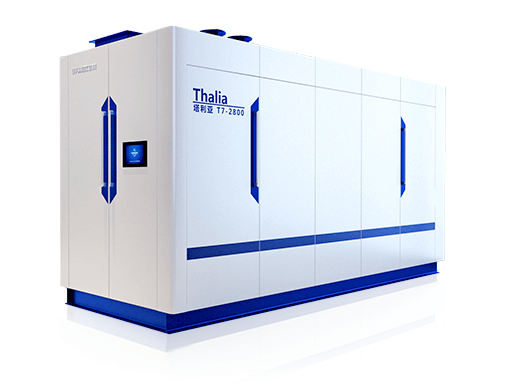

The company that cooperated with Zhengzhou Fangkuai Boiler this time is a grain and oil processing company located in Zhengzhou. Gas steam boilers are used in grain and oil production lines, and are mainly responsible for processes such as debromination, decolorization, fatty acids, and frying pans. In the process of processing soybeans into soybean oil, a large amount of high-temperature steam is required for drying, softening and heating, leaching and heating, separation and debromination, decolorization, refining and heating, etc.; more. The company has very high requirements for the quality of steam output by the boiler. After inspecting many boiler companies in the market, it decided to cooperate with Zhengzhou Fangkuai Boiler, which has more successful cases, to provide it with a gas steam with an output of 10 tons/hour. Boiler (WNS10-1.25-YQ), and supporting auxiliary equipment.